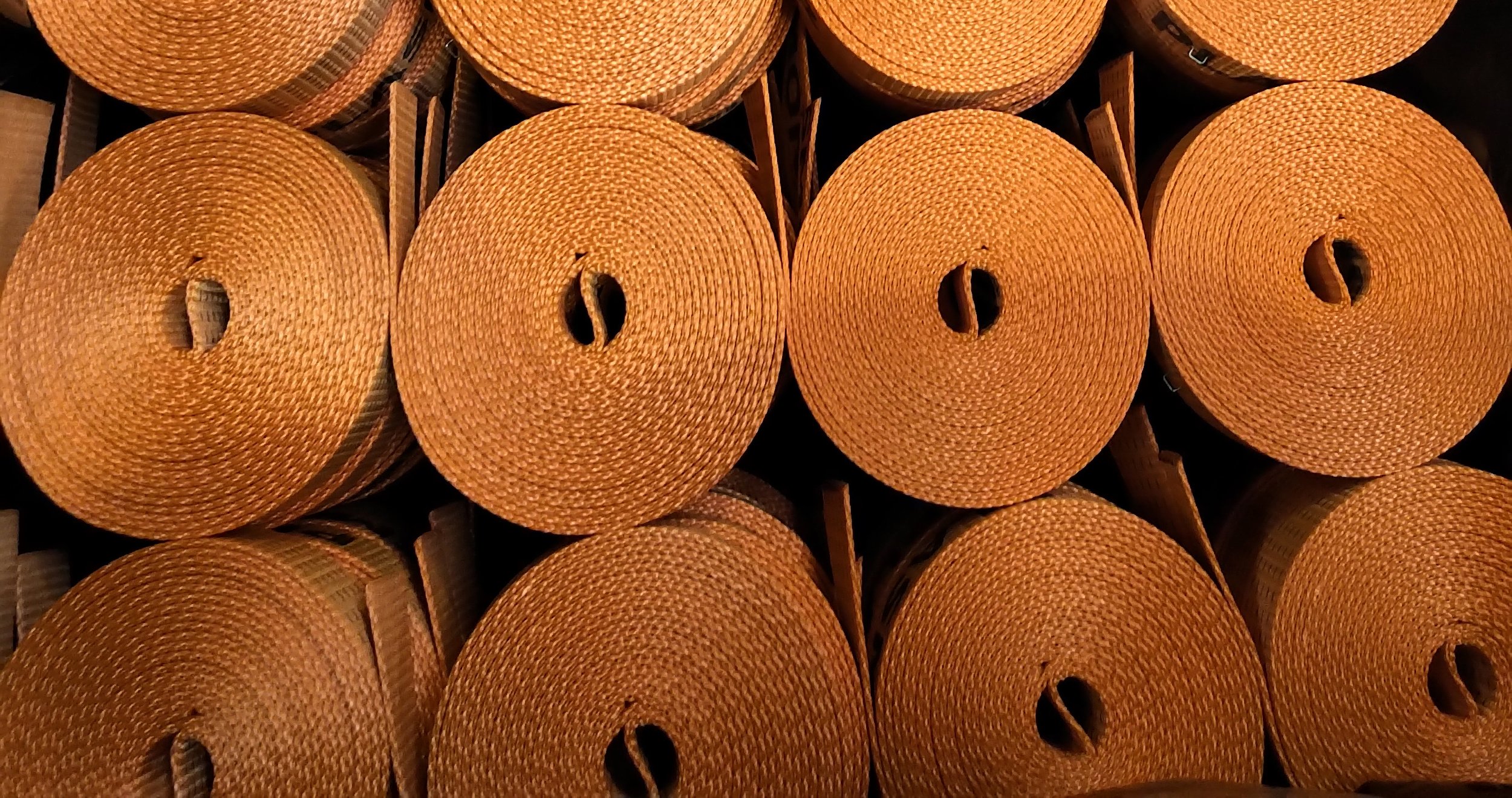

True innovators

We pride ourselves on being a market innovator, seamlessly integrating the latest techniques with quality raw materials and technical expertise to produce truly unique products.

Unique Finishes

Our range of state-of-the-art finishing machinery, combined with computerised colour-matching equipment, has enabled us to develop a comprehensive library of in-house processes, coatings, finishes, and colours.

-

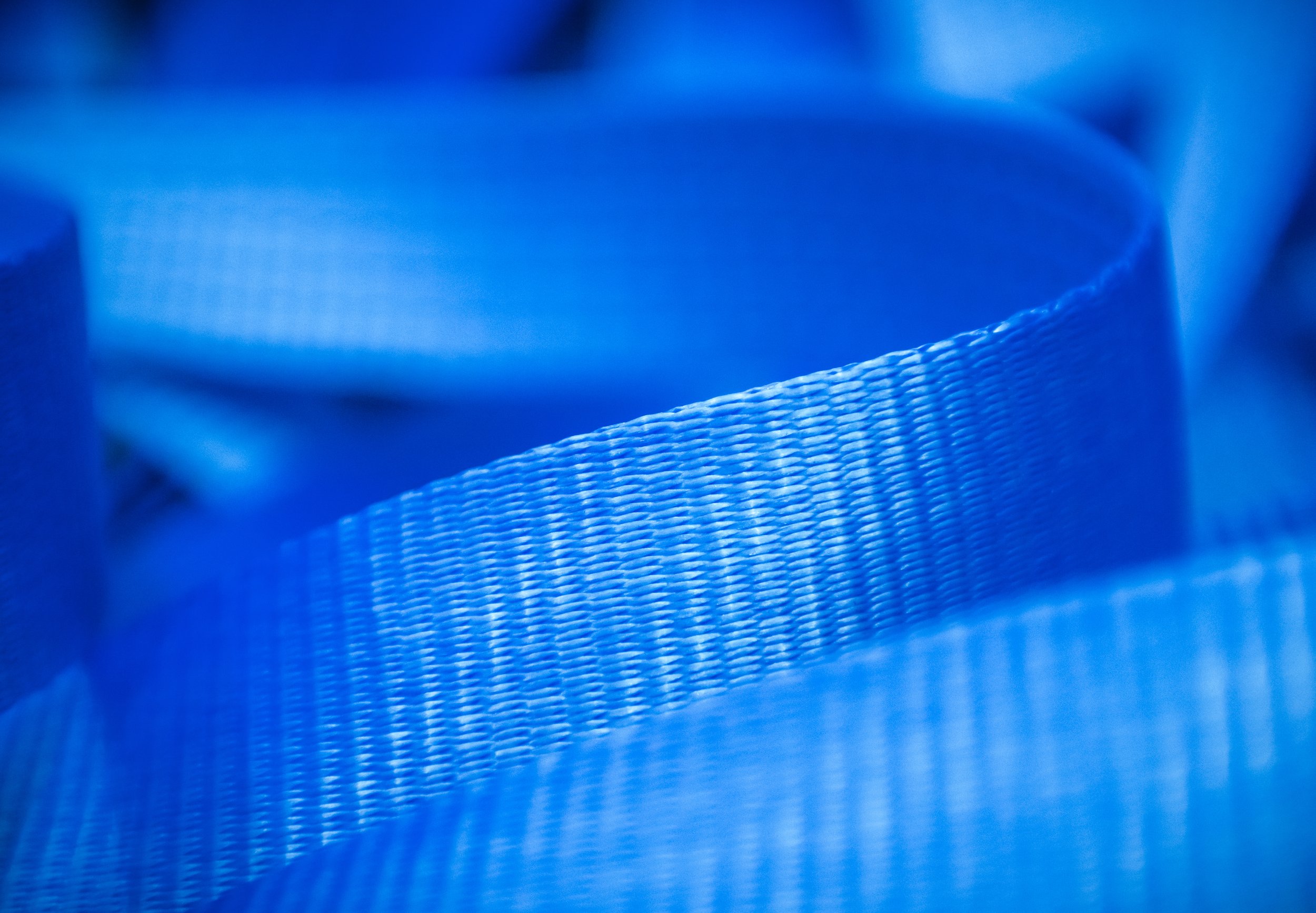

Tinted impregnations for colour coding and abrasion resistance using acrylic and polyvinyl copolymer, polyurethane, PVC and polyethylene emulsions, dyes and resins

Coloured plastisol coatings for products required in high frequency welding operations, or requiring exceptional wear resistance and outstanding UV stability utilising PVC, PVA, PVB, polyethylene and polyurethane pastes and emulsions

Polyester piece-dyeing for superior colour retention and excellent product aesthetics using proven industry-standard direct and disperse dyes

Supplementary oil & water repellents and anti-wick finishes for products used in extreme wet or contaminated environments

Flame retardants for products where heat and potential combustion are hazards to personal, property, asset or operational safety

Antimicrobial and antifungal coatings for use in environments where strict hygiene controls are critical and mandatory.

Collaboration

From bespoke fabrics to colours and finishes that are only limited by imagination. We collaborate closely with customers to develop products that not only perform exceptionally well but also look and feel fit for purpose, both technically and aesthetically.